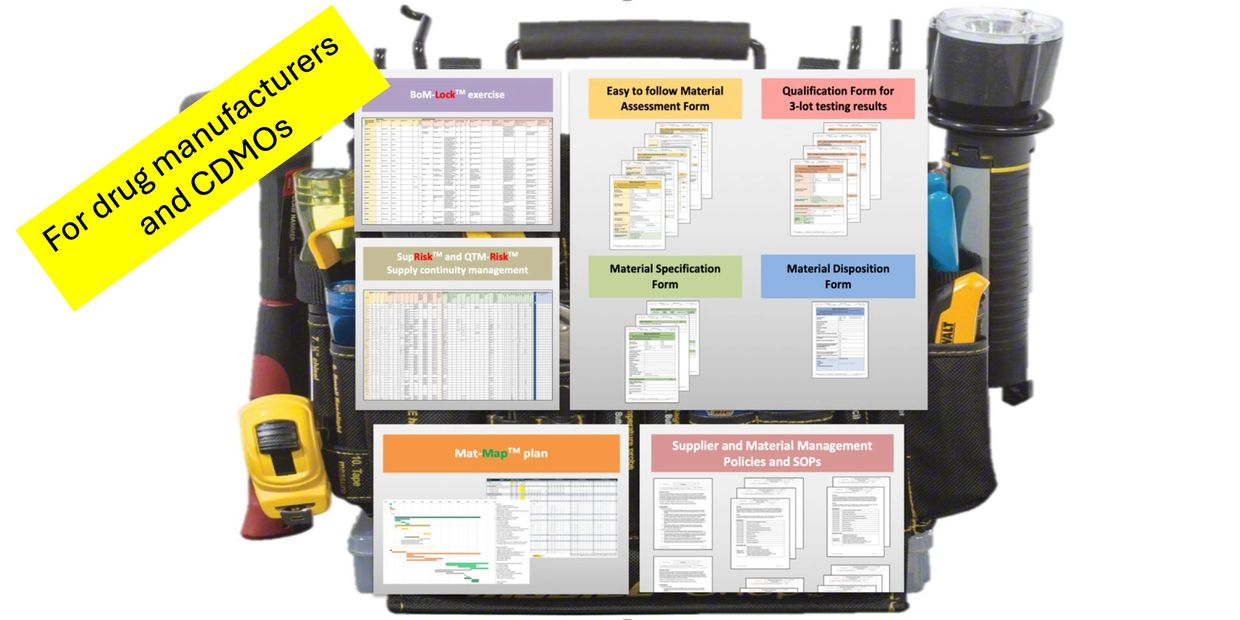

MatRisk™ for Material & Supplier Management

ProDeMaCon's Proprietary Toolbox

ProDeMaCon’s proprietary MatRisk™, our phase-appropriate Material & Supplier Management system, has already been successfully implemented at several CGT companies and CDMOs. Whether you are in early development or already in pivotal trials, it’s crucially important to plan for proper raw material onboarding & qualification while ensuring continuity of supply. Your Pharma, Biotech or Cell&Gene business depends on it.

For more information on the importance of proper Material & Supplier Management in Cell&Gene but also in Biotech, refer to our recently published article:

Best Practices For Raw Material And Supplier Management For Cell & Gene Therapy Manufacturing By Andreas M. Beckhaus and David J. Cady

Contact us for more information on MatRisk™.

Benefits

- Ready-to-implement toolbox

- Can be customized to your needs

- All necessary activities according to your project’s development phase

- Includes key SOPs and assessment & documentation forms

- Saves you thousands of internal FTE hours

- Ensures compliance for each stage of development

- Risk-based approach with fully documented justifications

- Prepares you for regulatory submissions and audits

Prioritizing All Your Raw Material Activities

During the BoM-Lock™ exercise, all raw materials (excipients, primary containers, starting materials such as vectors, reagents, buffers, single-use components etc.) on your Bill of Materials (BoM) are ranked by criticality to

- prioritize all material-related activities such as testing etc.

- identify critical materials that may need to be substituted

- start Material risk mitigation planning

- identify if RUO to GMP transitions needed

The BoM-Lock™ tool lets you easily prioritize your critical material activities to do the right thing at the right time

Planning Your Material Related Activities & Resources

The MatMap™ tool takes into account your timelines for First-in-Human, Pivotal Trial start, PPQ runs and IND and BLA filing plans etc. It will help you plan and budget phase-appropriately, identify critical tasks and dependencies for example for your testing plans. MatMap™ also helps you plan your resource needs by discipline over time for all material- and supplier-related activities.

Phase-Appropriate Raw Material Onboarding & Qualification

The raw material assessment form of the MatRisk™ toolbox is a "living" form that documents the phase-appropriate risk assessment for each material used in GMP production, considering among others:

- Potential impact on the final drug product's SISPQ (Safety, Integrity, Strength, Purity, Quality)

- Material qualification status and vendor data

- Supplier risk/status

- Material sterility assessment

- Adventitious / viral agents and TSE risk assessment

- Material particulates assessment

- Material stability assessment

- Material E & L and adsorptivity assessment

- Other additivity assessments (residual solvents, elemental impurities etc.)

- Manufacturer's specification appropriateness

Following Quality by Design (QbD) principles, potential Critical Material Attributes are determined for your Material Qualification and own testing plan as well as other attributes where you may rely on manufacturer testing.

Material Testing Documentation and Release Specification

Based on the draft Critical Material Attributes from the initial risk assessment, a testing plan is put together for your Material Qualification to transition from clinical specification to commercial specification.

Test results (typically from 3 different material batches) are documented and evaluated (e.g., by comparing your results with the manufacturer's CoA and vs. your own process needs) in the Material Qualification form, which will serve as the justification for your commercial specification.

All Key SOPs and Policies You Need for Compliant Material & Supplier Management

The SOP and policy templates from the MatRisk™ toolbox can easily be adapted and implemented according to your needs. They specify all necessary activities for material and supplier management phase-appropriately over the life cycle of the product. They work in conjunction with the other tools of the MatRisk™ toolbox.

Ensuring Uninterrupted Supply During Development & Commercial Phases

SupRisk™, the Supply Continuity tool of MatRisk™, will assess the available capacity, regulatory/quality maturity, and financial health of your suppliers. It will also assess for each raw material:

- the strategic fit (i.e., relative importance of your business based to the supplier based on their profile analysis)

- the ease of sourcing (i.e., difficulty of sourcing and qualifying an additional supplier)

- the sourcing diversification (i.e., how many supplier sites are available and/or qualified)

- the quality audit & compliance status

- the supplier quality history score and on-time performance score

This lets you easily prioritize your critical materials and suppliers in order to take appropriate actions such as SRM (Supplier Relationship Management), Inventory management, second sourcing, alternative sourcing etc.

Ensuring Uninterrupted Supply of Quality Testing Materials

QTM-Risk™, our additional Supply Continuity tool for all your quality testing and in-process control testing materials, will assess for each raw material used in Quality Control:

- Ease of Sourcing

- Supplier on-time supply history

- Supplier quality history

- Service history

It helps you prioritize your critical quality testing materials and suppliers in order to take appropriate actions such as SRM (Supplier Relationship Management), Inventory management, second sourcing, alternative sourcing etc.

Additional Forms You Need for Compliant Material & Supplier Management

Additional complementary template forms from the MatRisk™ toolbox include:

- Material Disposition Form

- Supplier Questionnaire